Good evening, this is Bono.

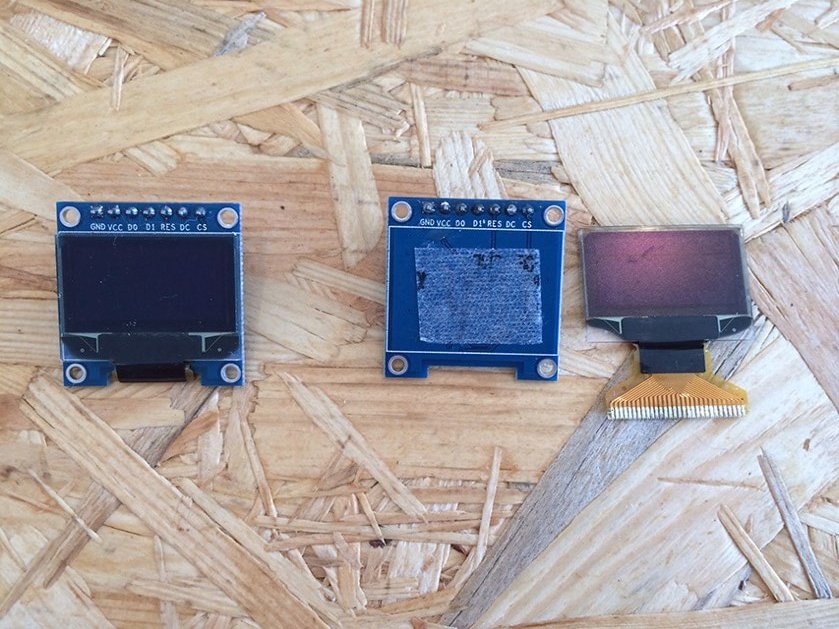

Recently, I wanted to use a small display of about 1 inch, so I searched around.

I have somehow figured out the points I need to be aware of, so I made a note of them.

Incidentally, OLED is often sold as OLED (Organic LED) displays, so try both when searching.

Key Points for OLED Display Selection

What size and shape do you want?

There are many display modules available, but not as many as you can freely choose from in terms of size and shape.

We often saw 1.5″, 0.96″, 0.66″, etc.

It is also important to choose between squares and rectangles. I have the impression that squares are less varied than rectangles.

What is the supply voltage?

It appears that OLED displays require a voltage of about 8V to 20V.

Note that some modules are equipped with DC/DC and can use the normally used 3.3V or 5V input, while others do not have DC/DC.

Note that for modules without DC/DC, it is necessary to provide separate power supplies for the display and for the signals/ICs.

What is the communication method?

Broadly speaking, both serial and parallel communications exist.

Parallel communication has more pins and less documentation, so serial communication is better if there are no particular restrictions.

However, the speed is naturally slower than parallel.

Do you have all the documentation and rarities in place?

Personally, I believe this is the most important.

Even though the display is small, it seems to be quite difficult to control.

(Maybe a software company could do this with ease, but…)

It would be a waste of time to waste time there, so we recommend that you Google as much as possible beforehand to see if you can find any examples of how it has been achieved in the configuration you want to use.

Color or black and white?

Basically, you will want to choose color, but you should be prepared to pay more than twice as much for color as for monochrome.

Monochrome is also available in two colors, blue and yellow, so if you want to keep prices low, please consider this option as well.

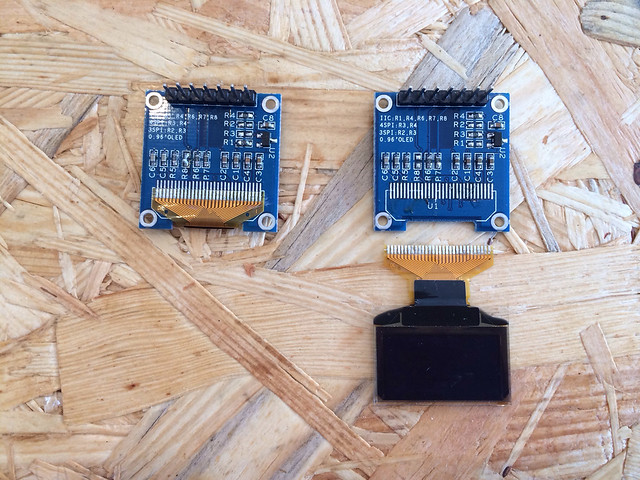

Is the interface with the display part a connector or direct connection?

Although often overlooked, it is quite important depending on how it is used.

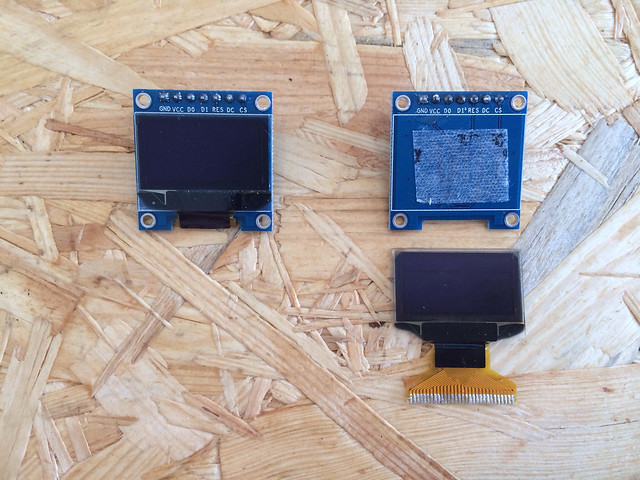

OLED displays are usually sold as a set of display and driver components.

However, the board on which the driver section is mounted is quite large because it is redundantly made with pin headers and mounting holes.

If you want to keep it as small as possible, that can be quite a bottleneck.

In such cases, it is better to make the driver board yourself.

(How to make a driver board is described in another article.)

The bottleneck there is the interface with the display part.

It is basically an FFC, but its pitch and tip shape differ.

First, the pitch varies from 0.5mm to 0.65mm, 0.7mm, and so on.

However, there is not that much variety in the opposite connectors, and you should expect only 0.5 mm or 1.0 mm.

Then what about other pitches? The only way to do this is to directly attach them to the board.

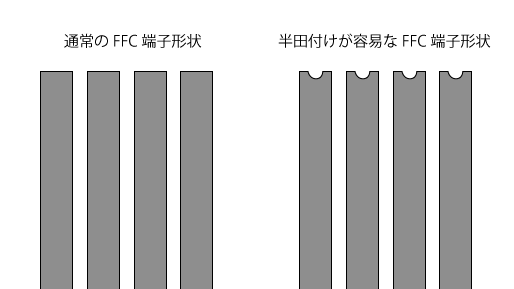

So the next point to note is that there are two types of direct soldering: those that are very difficult and those that are easy.

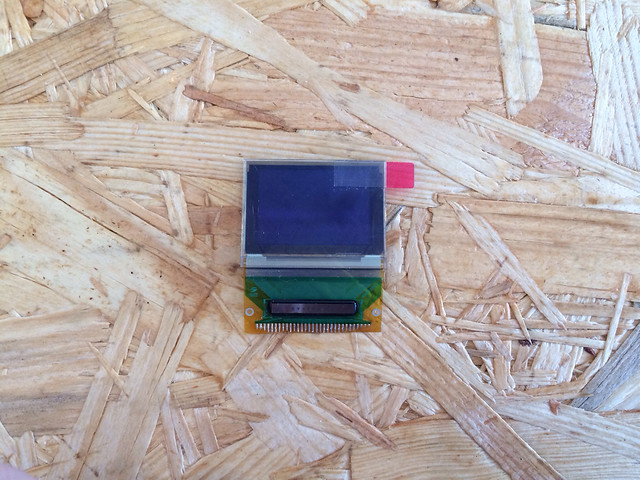

Difficult to install directly

Some of the copper parts of the terminals melt when you try to solder them.

For example, the module sold by aitendo below.

OLED module (96×64, 0.95″) – aitendo

Here is a picture of an actual failed attempt at soldering.

I failed once, cut the substrate in the melted area and tried again, but it melted again.

Easy direct mounting type

On the other hand, some types are easier to solder than others.

For example, the following HiLetgo products have an ingenious terminal tip shape.

It is hard to tell from the picture, so I made a drawing.

When the above terminal is magnified with a loupe, the tip is rounded and concave, as shown on the right in the figure below. This is thought to take advantage of the surface tension of the solder to make it easier for the solder to adhere to the terminals.

In fact, the soldering was relatively easy.

However, it is difficult to determine the tip shape from a photograph alone, so the only way is to visit the store in person or, if it is still difficult to determine the tip shape, to actually try it out.

(Incidentally, it is not impossible to solder the normal FFC shape as well.)

introduction

I found very little information on how to handle small displays, either on the Internet or in books.

The following book was the most helpful of them all.

It contains information on how to set up and connect small displays, including LCD as well as OLED.

The display list page on pages 22-23 is particularly impressive, listing more than 40 modules with display sizes, operating voltages, interfaces, etc.

Please take a look at our display selection.

Start electronics

Start electronics