YouTube

0:00 Opening

0:22 Wait!

1:17 Quick!

1:55 A little bit!

2:21 One Point Advice

2:57 Summary

How to solder well

In this issue, we would like to introduce how to solder well.

To be honest, I am still far from the level of an expert, but I have summarized three points that are commonly said to be important, and I believe that if you are aware of these points, your soldering skills will improve dramatically.

If you have been doing soldering somehow, or if you are having trouble getting it right, please take a look at this page.

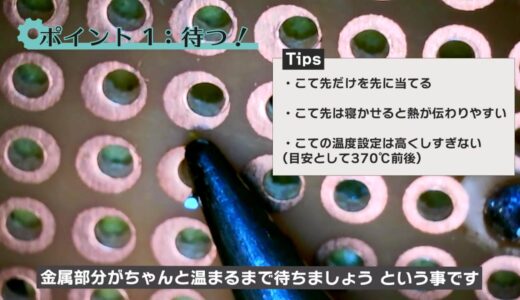

Wait!

The first point is to wait.

First, apply only the tip to the board or component terminals and wait until the metal parts are properly warmed up.

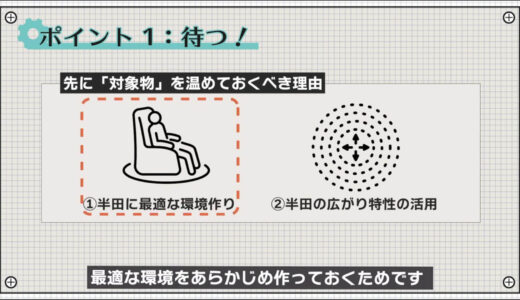

There are two reasons for this: one is to create in advance the optimum environment for the solder to bond with the mating metal.

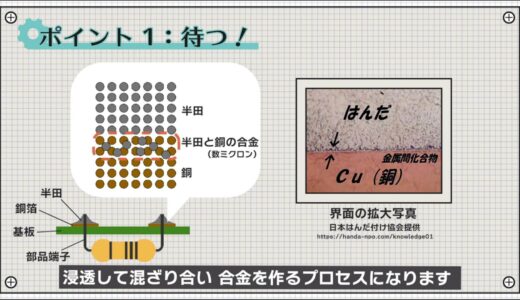

Soldering is technically a process in which solder penetrates the surface of the mating metal and mixes with it, creating an alloy.

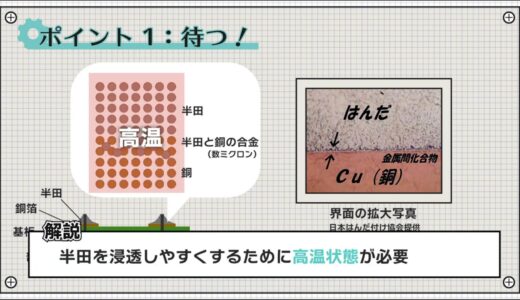

At this time, it is necessary to create some high temperature conditions for penetration.

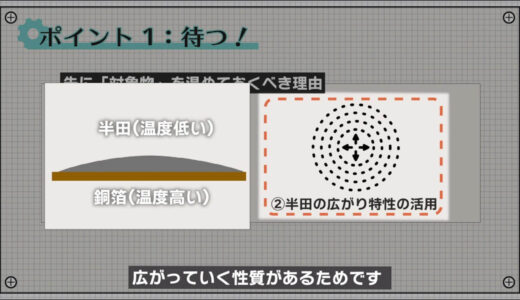

The other reason is that when solder becomes a liquid, it has the property of spreading from a lower temperature to a higher temperature.

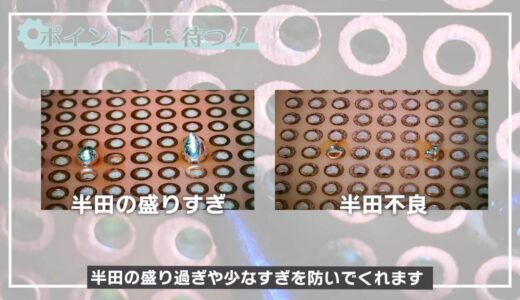

By using this property, by warming the area to be soldered first, the solder will spread on its own, preventing too much or too little solder.

In the beginning, it is easy to get in a hurry and apply solder right away, but it is just right to calmly count 3 seconds slowly in your mind after applying the soldering iron to the board and components.

Parts are also fine, as they will basically never break after this amount of time! !!!

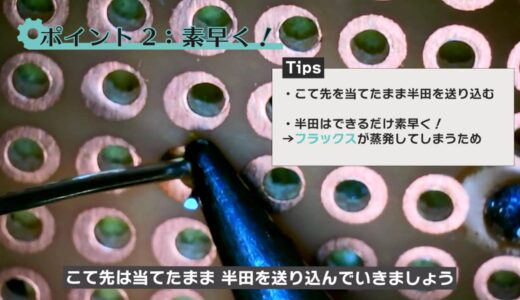

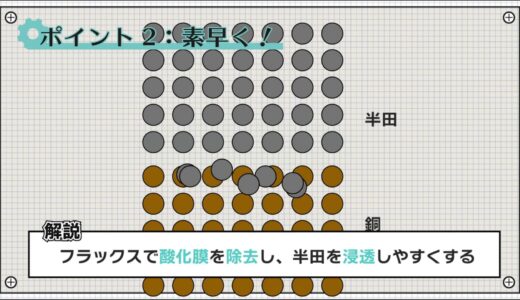

Quickly!

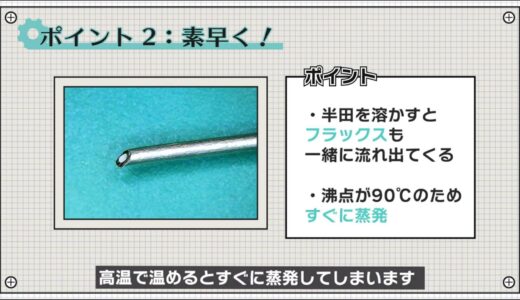

The next point is to do it quickly.

Keep the iron tip applied and feed in solder.

At this point, the key is to feed the solder in as quickly as possible.

This is because soldering must be completed before the flux evaporates.

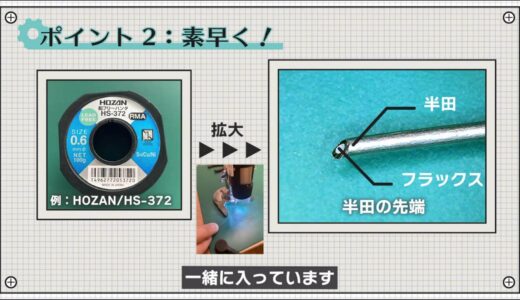

In fact, solder contains a material called flux inside with it.

Flux chemically removes the oxide film on the metal surface and facilitates the penetration of solder.

When solder is melted, flux is also dissolved together as a liquid. In fact, this flux has a low boiling point and evaporates quickly when heated at high temperatures.

Also, since solder becomes brittle if its temperature rises too high, it is important from the standpoint of strength to quickly send solder with a relatively low temperature to cool it down so that the temperature does not rise too high.

Just a few!

The last point is that the amount of solder to be fed in is only a small amount.

As is often said, good soldering produces what is called a fillet, a beautiful curve like Mt.

It is easy to put on too much solder, but too much solder will form a dumpling-like shape and reduce reliability because it is impossible to check whether the root is properly soldered.

Extremely low solder content also causes insufficient solder spreading, which can lead to contact defects and other problems.

Experienced technicians quickly feed in the appropriate amount of solder based on their experience in determining how much is enough to produce a clean fillet.

advice of a point (advice that may be helpful to some people)

Here is one piece of advice.

For good soldering, it is important to maintain the soldering iron as well as the work.

If there is rust or debris on the tip, the heat from the tip cannot be fully transferred to the board and solder.

After warming up the trowel tip, first clean it with a sponge or metal cleaner.

And after the soldering work is finished, do not turn off the power supply as it is, but rather, put solder on the tip of the iron before turning it off.

Since the tip is metal, if it is left as is, it will oxidize, but if solder is applied, it will act as a coating and prevent oxidation.

summary

In this article, we have introduced the key points of successful soldering.

Soldering may seem simple at first glance, but in fact it is a world so deep that a whole book could be written just on it.

This is a very important task that can reduce the reliability of the circuit if not done correctly , so at a minimum, keep in mind at least the three points introduced here.

Start electronics

Start electronics